To prevent global temperatures from increasing by more than 1.5 degrees Celsius, it is essential to cut emissions in half by 2035, despite the likelihood of another record year for burning fossil fuels. However, the impressive engineering showcased in this year’s award-winning projects offers hope that we can meet this challenge. Innovations such as a new type of thermal battery, inexpensive lasers for steelmaking, and AI-formulated vegan cheese demonstrate the potential for positive change in various industries.

(Editor’s Note: This is a section from Popular Science’s 37th annual Best of What’s New awards. Be sure to read the full list of the 50 greatest innovations of 2024.)

Grand Award Winner

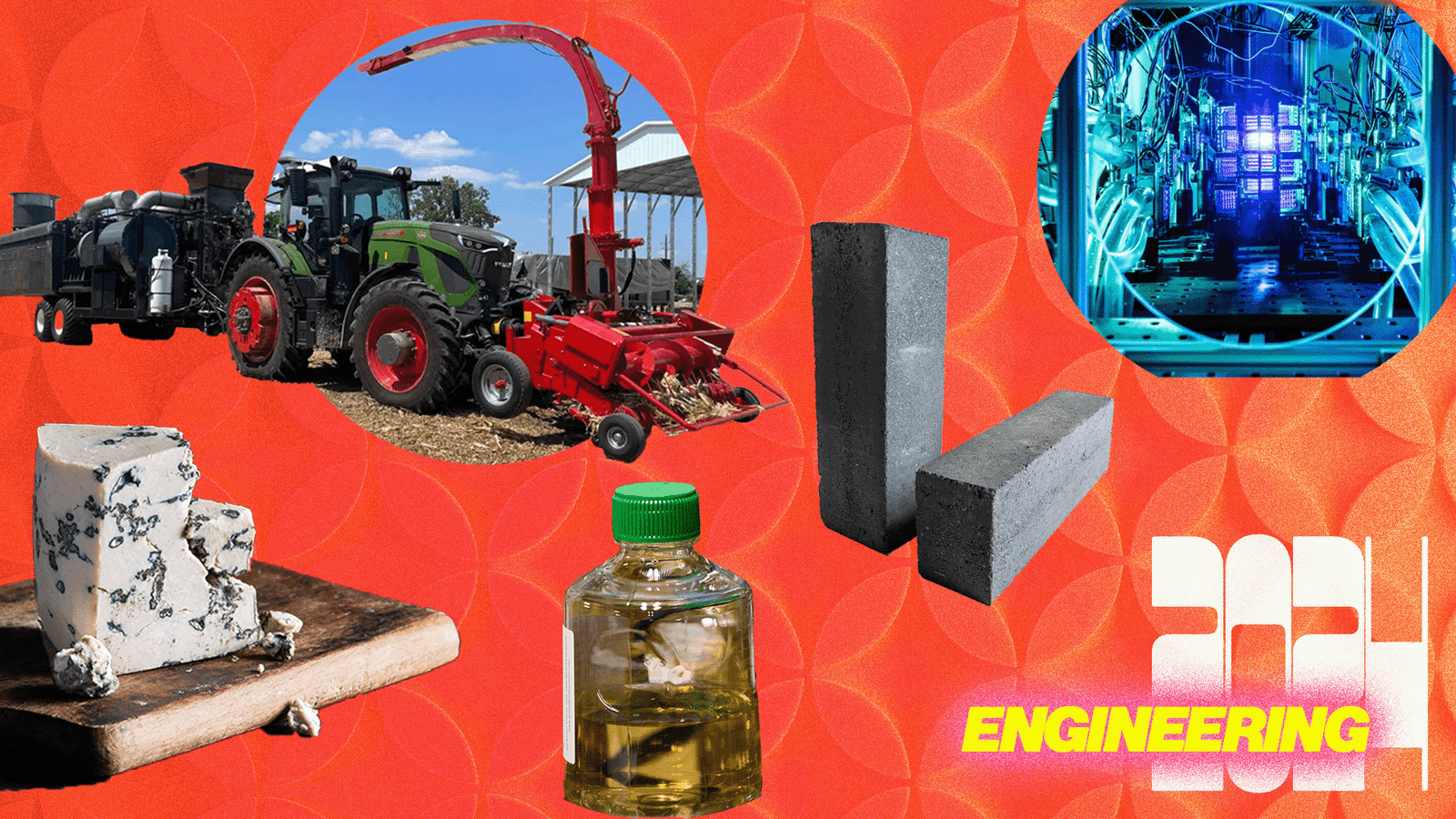

Joule Hive “firebrick” thermal battery by Electrified Thermal Solutions (ETS): A cleaner 21st-century firebrick

Despite the decreasing costs of wind and solar energy, the high costs of batteries remain a significant obstacle to decarbonizing the economy. Industries like cement, steel, and chemicals, which rely on high temperatures and continuous furnace operation, contribute about 17% of the world’s CO2 emissions by burning fossil fuels for heat. The Joule Hive offers a solution to this challenge by using clean electricity to maintain high temperatures in a container filled with heat-storing ceramic bricks. These bricks, developed through years of research at MIT, are electrically conductive and provide insulation to retain heat efficiently.

Unlike traditional heating elements that burn out over time, the oxidized Joule Hive firebricks reach higher temperatures and require less maintenance. Studies have shown that widespread deployment of firebricks heated by renewable electricity could eliminate 90% of the fossil fuels currently burned by heavy industries for heat. ETS plans to deploy a commercial-scale Joule Hive at San Antonio’s Southwest Research Institute in 2025.

Mobile biochar farm robot by Applied Carbon: Converting agricultural waste into biochar in the field

Nine of the top ten companies that have successfully removed carbon from the environment utilize modern biochar production methods. Applied Carbon’s innovation lies in developing a pyrolyzing chamber capable of handling large volumes of agricultural waste, such as corn and wheat stalks, at a field level. By pyrolyzing this waste, the robot produces biochar and synthesis gas, which is then used to maintain high temperatures in the chamber. This on-field production process eliminates the need to transport the waste to a central facility, reducing emissions and costs. Applied Carbon has already deployed robots in corn fields to convert waste into biochar, with plans to scale up production for significant carbon sequestration benefits.

GreenLight Biosciences’ Calantha offers a precision solution to combat the Colorado potato beetle, a notorious pest in agriculture. By using double-stranded RNA to disrupt the beetle’s essential protein production, Calantha acts as a targeted biopesticide with minimal impact on non-target species. This innovative approach leverages Nobel Prize-winning technology to deliver a highly effective pest control solution with minimal environmental impact.

Climax Foods has revolutionized the plant-based cheese industry by developing AI-formulated vegan cheeses that mimic the taste and texture of dairy cheese. By using AI algorithms and input from expert cheesemakers, Climax Foods has created plant-based cheese formulations that rival traditional dairy products in flavor and quality. Their success in producing delicious vegan blue, brie, and feta cheeses has garnered critical acclaim and consumer interest, setting a new standard for plant-based dairy alternatives.

Laser furnace by Limelight Steel: Laser processing of iron ore for steel with 95% fewer emissions